In the rapidly evolving realm of scientific research, the importance of high-quality equipment cannot be overstated. At the heart of many innovative discoveries lies the Physics Laboratory Bench, a crucial workspace that supports the experimentation and exploration of fundamental principles. As laboratories worldwide strive for excellence, the demand for superior manufacturing processes has surged, leading to groundbreaking advancements in the production of these essential benches. This blog will delve into the global innovations in the manufacturing of Physics Laboratory Benches, showcasing how cutting-edge technology, meticulous craftsmanship, and an unwavering commitment to quality are setting new standards in the industry. By exploring various trends and practices, we will highlight the pivotal role these benches play in fostering an environment conducive to research and education, driving the scientific community toward a future filled with potential breakthroughs.

The Evolution of Physics Laboratory Bench Manufacturing: An Industry Overview

In recent years, the manufacturing landscape for physics laboratory benches has undergone a significant evolution, emphasizing the importance of quality and innovation. Advances in materials and design have contributed to creating benches that offer better durability, adaptability, and functionality. With the integration of modern technology, laboratories can now benefit from features that enhance workflow and efficiency, making them more conducive to high-level research.

One of the exciting developments in this field is the application of physics-guided methodologies to optimize manufacturing processes, such as in additive manufacturing. For instance, recent challenges in the industry have highlighted the value of precise thermal management, where understanding the heat sources at play can lead to predictable outcomes in manufacturing. This shift not only raises the bar for production quality but also aligns with the growing demand for sustainable practices in laboratory setups.

Tips: When selecting a physics laboratory bench, consider the specific needs of your research environment. Look for customizable options that can accommodate various equipment setups. Additionally, assess the thermal properties of materials used to ensure optimal performance, especially if your work involves advanced manufacturing techniques. Be proactive in exploring new technologies that can enhance your laboratory’s capabilities.

In the rapidly evolving field of laboratory infrastructure, innovative approaches in the manufacturing of laboratory benches are significantly enhancing quality and functionality. One of the key innovations driving this transformation is the integration of advanced materials, such as high-grade stainless steel and innovative composites, which ensure durability and resistance to chemical spills. These materials not only extend the lifespan of the benches but also meet stringent safety standards, making them indispensable for any laboratory environment.

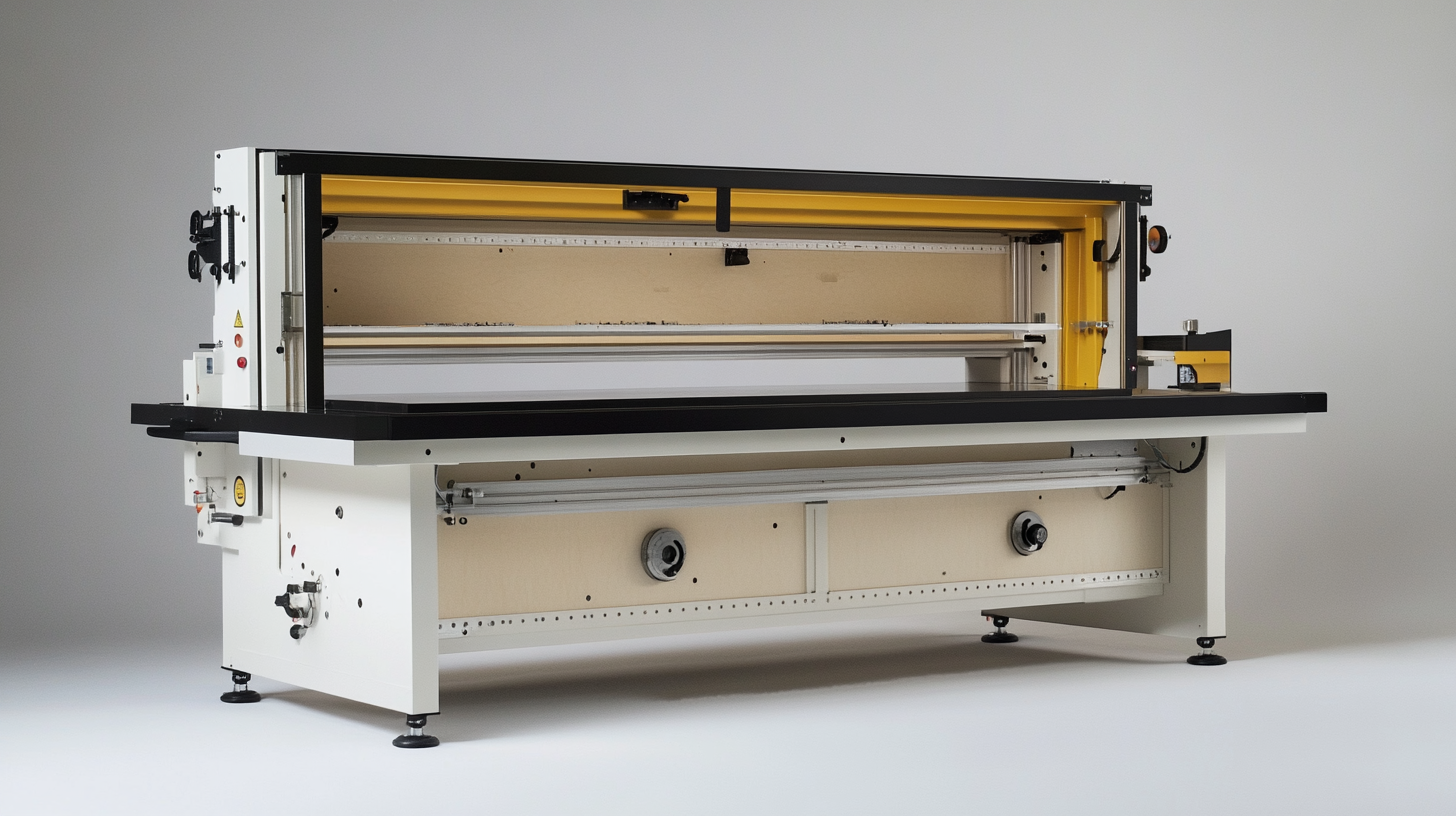

Another critical factor in improving quality in laboratory bench production is the incorporation of modular designs. This allows for customization based on specific laboratory needs and workflows, providing greater flexibility. Moreover, modern manufacturing techniques, such as precision CNC machining and automated assembly lines, are streamlining production processes. This not only ensures consistency in quality but also reduces lead times and costs. As a result, laboratories can now access high-quality, tailored solutions that enhance productivity and foster scientific advancements.

The demand for high-quality physics lab benches is projected to surge by 2025, driven by advancements in educational methodologies and increased investment in research and development. As educational institutions and research facilities strive to enhance their infrastructure, the need for durable, ergonomic, and multifunctional lab benches becomes increasingly critical. This shift aligns with a broader trend toward creating modernized learning environments where students can engage in hands-on experiments without compromising on safety and efficiency.

In response to this growing demand, manufacturers are focusing on innovation and quality assurance in their design and production processes. The integration of advanced materials and technologies is being prioritized to ensure that lab benches not only meet but exceed the requirements of contemporary physics laboratories. Enhanced features such as adjustable heights, integrated storage solutions, and modular designs are becoming standard, allowing for versatile use across different types of experiments. As the market continues to evolve, stakeholders must remain aware of these trends to ensure they are prepared to meet the expectations of future users, ultimately contributing to breakthroughs in education and research.

In recent years, sustainability has emerged as a critical focal point in manufacturing, particularly in the realm of laboratory bench production. According to a report from the International Journal of Sustainable Manufacturing, nearly 75% of manufacturers now prioritize eco-friendly materials in their processes. This shift not only meets regulatory requirements but also responds to the growing consumer demand for products that have minimal environmental impact.

Eco-friendly materials, such as recycled plastics and sustainably sourced wood, provide excellent alternatives to traditional materials. A study by the Sustainable Materials and Manufacturing Consortium highlights that using recycled materials can reduce carbon emissions by up to 60%. By integrating these sustainable practices, laboratory bench manufacturers can significantly enhance their product lifecycle and reduce waste, while also contributing to a circular economy. As innovation continues to drive the industry, the combination of high-quality craftsmanship and environmental stewardship is becoming a standard—a trend that not only benefits the planet but also positions companies as leaders in the modern manufacturing landscape.

| Feature | Description | Eco-Friendly Material | Sustainability Rating |

|---|---|---|---|

| Bench Structure | Robust and stable design suitable for various experiments | Recycled Steel | A+ |

| Surface Material | Durable surface resistant to chemicals and wear | Biobased Epoxy Resin | A |

| Drawer/Storage | Spacious storage with eco-friendly designs | Sustainable Wood | B+ |

| Assembly Process | Efficient assembly reducing energy consumption | Low VOC Adhesives | A |

| Longevity | Designed for long-term use without deterioration | Recyclable Materials | A++ |

In the world of physics laboratory bench manufacturing, quality is paramount. Innovators across the globe are setting benchmarks with their groundbreaking approaches and technologies. One notable case study involves a small startup that revolutionized lab bench design by integrating modular components, allowing researchers to customize their workspaces based on specific experiments. This flexibility has led to increased efficiency and a significant reduction in setup time, positively impacting research outcomes in various physics disciplines.

Another compelling success story comes from an established manufacturer that adopted sustainable materials in their production process. By utilizing recycled composites, they not only enhanced the durability of their lab benches but also minimized their carbon footprint. The response from the scientific community has been overwhelmingly positive, as users appreciate the dual benefits of high-quality equipment that aligns with their commitment to environmental responsibility. These examples of innovation highlight how forward-thinking companies are transforming the landscape of physics lab bench manufacturing, pushing the boundaries of what is possible in laboratory settings.